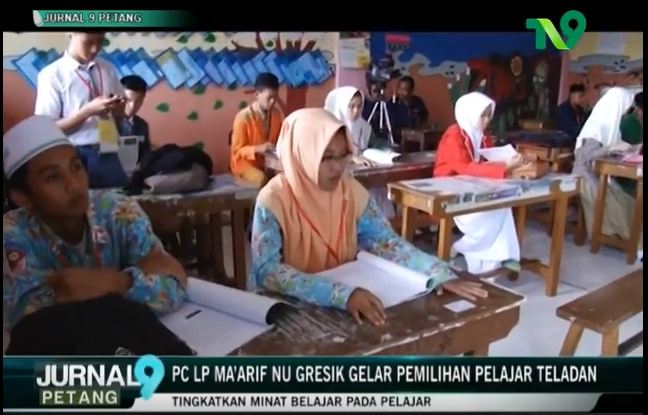

PC LP Maarif NU Gelar Pemilihan Teladan ke 39 di Yayasan Pondok Pesantren Qomarudin, Sampurnan, Gresik. Berlangsung Menarik. Pemilihan Pelajar Bertujuan agar menjadi teladan bagi para pelajar lainnya. Pemilihan ini diikuti 390 Pelajar se Kabupaten Gresik

Home

BERITA VIDEO

Gresik: Bentuk Karakter ASWAJA LP Maarif NU Gresik Gelar Pemilihan Pelajar Teladan - Jurnal9

Gresik: Bentuk Karakter ASWAJA LP Maarif NU Gresik Gelar Pemilihan Pelajar Teladan – Jurnal9

Recommendation for You

Bantuan untuk Korban Banjir Lamongan terus berdatangan, salah satunya dari PT Siantar Top. penyaluran dibantu…

Ribuan Eleman Warga NU mulai Pondok Pesantren hingga Banom NU turut memeriahkan #HaulMuasisNUSumenep yang dilaksanakan di…

Certains logiciels détectent les informations d’enregistrement d’écran et ne peuvent pas prendre de capture d’écran du téléphone mobile. Dans ce cas, vous pouvez utiliser la surveillance à distance pour afficher le contenu de l’écran d’un autre téléphone mobile.

MyCellSpy est une application puissante pour la surveillance à distance en temps réel des téléphones Android. https://www.mycellspy.com/fr/tutorials/how-to-install-spy-app-to-track-someone-phone-for-free/

vibration analysis

The Cruciality of Vibration Control Equipment in Mechanical Systems

Within industrial sites, machines as well as turning devices serve as the support of manufacturing. Nonetheless, a of the commonly prevalent problems which may affect their performance as well as lifetime exists as oscillation. Vibration might bring about a series of issues, ranging from reduced precision as well as productivity resulting in increased wear and tear, finally bringing about high-cost downtime as well as restoration. Such a situation is why vibration management systems proves to be necessary.

Why Vibration Control is Critical

Vibration in equipment might cause various negative impacts:

Decreased Operational Effectiveness: Excess vibrations could result in discrepancies as well as unbalance, lowering the effectiveness of the equipment. This can lead to slower output times along with increased electricity usage.

Heightened Wear and Tear: Ongoing oscillation speeds up total damage to machinery parts, resulting in more frequent maintenance and the risk of unexpected issues. This does not just heightens operating costs as well as decreases the lifespan of your equipment.

Safety Risks: Unmanaged resonance could pose substantial safety risks for both the machines along with the personnel. In, extreme situations, this may result in disastrous equipment failure, jeopardizing operators as well as bringing about extensive devastation to the environment.

Precision and Production Quality Issues: In fields where rely on high precision, including manufacturing as well as aerospace, oscillations can lead to flaws with the production process, producing defective products and increased waste.

Economical Approaches towards Vibration Management

Investing in resonance control apparatus proves not just necessary and also a prudent choice for all businesses that any industry that relies on machines. Our advanced vibration management systems are designed to designed to mitigate vibrations from all mechanical systems or rotational systems, providing smooth and efficient operations.

What sets our tools apart is its cost-effectiveness. We understand the importance of cost-effectiveness in the modern competitive marketplace, which is why our offerings include premium vibration management solutions at prices that won’t break the bank.

By choosing our systems, you’re not only preserving your machinery along with boosting its efficiency but also investing in the long-term achievement of your operations.

Conclusion

Oscillation control is a vital aspect in ensuring the effectiveness, safety, as well as lifetime of your machinery. With our cost-effective resonance mitigation apparatus, you can ensure your processes function efficiently, your products remain top-tier, along with all personnel stay safe. Don’t let oscillation compromise your company—invest in the proper tools today.

ile kosztuje prawo jazdy am

Теперь вы можете скачать легальные БК и делать ставки на любые спортивные события прямо с телефона

Для непрерывного доступа установите 888starz apk ios

Увеличьте видимость сайта в поиске с помощью сервиса накрутки ПФ и улучшите SEO.

Для игры в слоты скачайте 1xslots на нашем сайте.

Перед началом игры изучите Lucky Jet отзывы реальных игроков.

Отзывы о Lucky Jet подскажут, как лучше управлять ставками и рисками.

Изучите советы других игроков с Lucky Jet отзывы реальных игроков.

Промокод лаки джет поможет вам начать с бонусами и увеличить шансы на успех.

Чтобы наслаждаться игрой, просто скачайте легальные БК и начните выигрывать на спортивных событиях

Мобильные ставки доступны каждому — просто скачайте легальные БК и начните выигрывать

Надежные мобильные приложения для ставок на спорт позволяют делать ставки в любое время. Скачайте их бесплатно — скачать легальные БК

Приложения для ставок на Android помогают делать ставки на спорт с вашего смартфона. Скачайте их прямо сейчас — скачать БК на Android

Узнайте больше о вывозе строительного мусора в Новосибирске https://prochepetsk.ru/evolyuciya-sistemy-vyvoza-musora

Скачать Lucky jet можно за пару минут и сразу приступить к игре.

Скачайте Лаки джет и начните зарабатывать на увлекательной игре.

Для тех, кто хочет адреналина и денег, игра ракета на деньги станет идеальным выбором.

Скачайте Лаки джет, чтобы открыть для себя новый источник дохода.

Unlock rewards with 888Starz promo code 888LEGAL and enhance your gaming experience.

Access live sports betting on 888Starz Bet and boost your winnings with bonuses.

Unlock special rewards with 888Starz promo code 888LEGAL and maximize your experience.

Play premium games on 888Starz Casino and enjoy rewards with promo code 888LEGAL.

Con la 1xslot app, disfruta de juegos de casino sin limites.

Lleva el entretenimiento a otro nivel con 1xslots movil y juega donde quieras.

скачать приложения онлайн казино https://misacanon.com/kometa-casino-oficialnyj-sajt-rabochee-zerkalo/

закачать приложения казино https://www.fedclear.co.za/vse-pro-igornyj-biznes-v-delovom-onlajn-izdanii-3/

закачать приложения онлайн казино https://www.diariofmmacapa.com.br/onlajn-kazino-v-ukraine-rejting-top-kazino-na-2/

закачать приложения казино https://isei.edu.mx/onlajn-kazino-s-minimalnym-depozitom-10-grn-2/

Оставайтесь в игре с актуальным 1xslots зеркалом рабочим на любой день.

Пользуйтесь 1xslots мобильной версией для игры на ходу.

Играйте без ограничений с 1xslots приложением на андроид.

Как начать играть в 1xSlots https://aztarna.es/pages/1xslots-casino_15.html

Подробная информация об 1xSlots https://aztarna.es/pages/1xslots-casino_15.html

Максимизируйте выигрыши с 1xslots бонус кодом.

Играйте где угодно с 1xslots мобильной версией.

Узнать больше о 1xSlots https://antiguedadeselrodeo.com.ar/pages/1xslots-argentina.html

Лучшие фишки 1xSlots https://santaeugenia.archimadrid.es/pags/1xslots-casino-argentina_1.html

Узнай больше про 1xSlots https://davisa.es/page/1xslots-casino-argentina.html

Juega en 1xslots casino https://antiguedadeselrodeo.com.ar/pages/1xslots-argentina.html

Tutorial para 1xslots casino https://nodosde.gob.ar/pgs/1xslots-descargar_1.html

Snel toegang tot CorgiSlot https://wildlife.berkeley.edu/cawolfproject/get-involved/

Laatste nieuws over CorgiSlot https://welling.domains.unf.edu/member.php?action=profile&uid=4198

Gratis download van CorgiSlot https://zingenindezomer.nl/test/pgs/?corgislot-beste-online_casino.html

análisis de vibraciones

Equipos de equilibrado: importante para el rendimiento suave y óptimo de las dispositivos.

En el campo de la innovación contemporánea, donde la rendimiento y la confiabilidad del aparato son de máxima relevancia, los dispositivos de equilibrado juegan un tarea crucial. Estos aparatos especializados están desarrollados para ajustar y regular componentes giratorias, ya sea en equipamiento manufacturera, medios de transporte de transporte o incluso en electrodomésticos hogareños.

Para los especialistas en conservación de equipos y los profesionales, operar con aparatos de balanceo es importante para asegurar el funcionamiento estable y fiable de cualquier sistema rotativo. Gracias a estas alternativas avanzadas modernas, es posible reducir considerablemente las movimientos, el ruido y la carga sobre los soportes, extendiendo la longevidad de piezas importantes.

De igual manera importante es el papel que cumplen los aparatos de balanceo en la asistencia al cliente. El asistencia experto y el mantenimiento constante usando estos aparatos permiten dar soluciones de excelente nivel, elevando la bienestar de los usuarios.

Para los propietarios de empresas, la inversión en sistemas de balanceo y detectores puede ser esencial para aumentar la productividad y rendimiento de sus sistemas. Esto es particularmente significativo para los emprendedores que dirigen pequeñas y intermedias organizaciones, donde cada punto es relevante.

Por otro lado, los sistemas de balanceo tienen una gran uso en el sector de la protección y el supervisión de estándar. Posibilitan detectar posibles fallos, previniendo arreglos onerosas y perjuicios a los sistemas. Más aún, los resultados recopilados de estos equipos pueden utilizarse para optimizar sistemas y aumentar la exposición en plataformas de investigación.

Las campos de aplicación de los equipos de equilibrado abarcan múltiples sectores, desde la producción de transporte personal hasta el monitoreo del medio ambiente. No afecta si se considera de enormes fabricaciones productivas o reducidos locales caseros, los sistemas de balanceo son fundamentales para promover un rendimiento efectivo y sin fallos.

Explore the ranked best online casinos of 2025. Compare bonuses, game selections, and trustworthiness of top platforms for secure and rewarding gameplaycrypto casino.